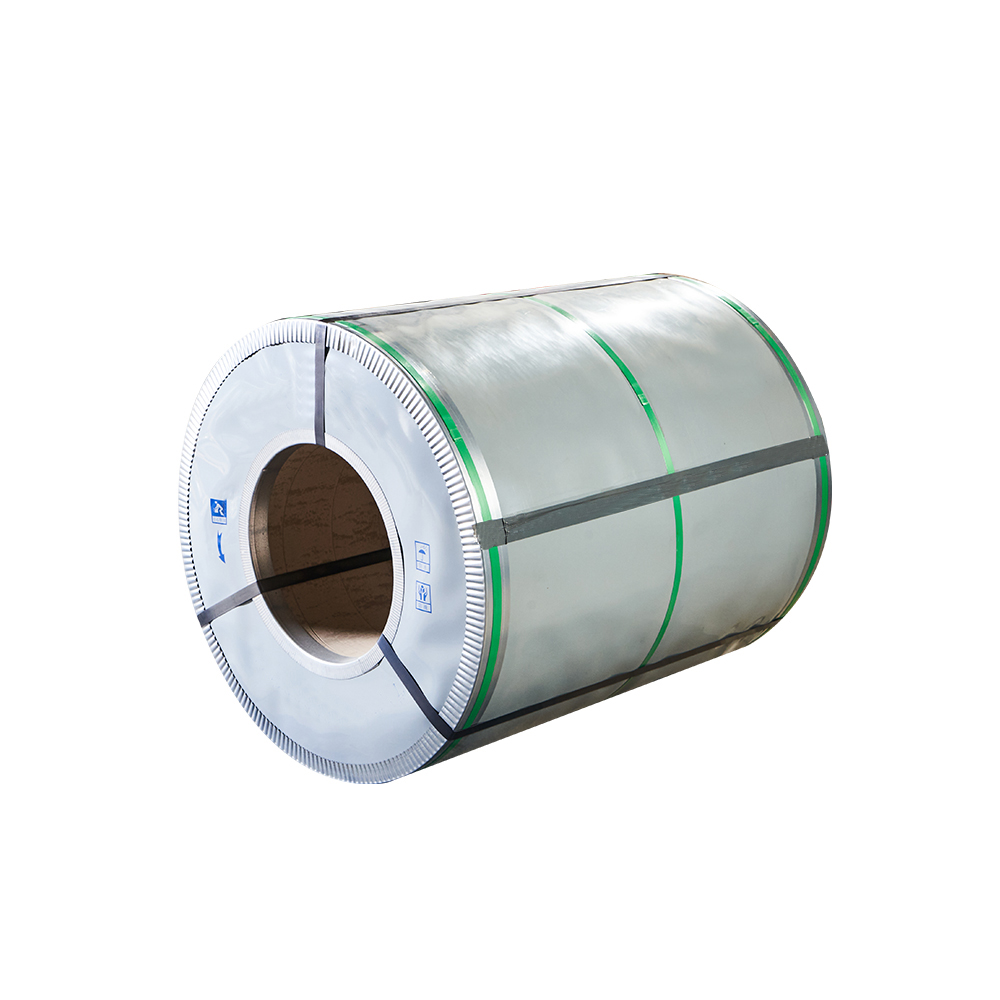

Widely used type 201 stainless steel strips

Xinjing is a full-line processor, stockholder and service center for various of cold-rolled and hot-rolled stainless steel coils, sheets and plates, for over 20 years. Our cold rolled materials all are with international standards, and precision enough on flatness and dimensions Our smart and precision cutting & slitting services can meet various demands, while the most skilled technical advises are always available.

Products Attributes

- Type 201 is an austenitic chromium-nickel-manganese stainless steel that was developed in the 1950’s due to worldwide nickel shortages and soaring nickel prices.

- With higher hardness and less toughness. Its manganese and nitrogen are partially substituted for nickel.

- Without as much nickel, it is not as effective at preventing corrosion.

- Composed with more manganese and nitrogen, type 201 stainless steel is especially helpful in cold environments, as its toughness holds up in cold weather.

- Easily beats some metals (carbon steel, aluminum, etc.) in corrosion resistance.

- 201 stainless has high spring back property.

- Low electrically and thermally conductive.

- Type 201 is non-magnetic in the annealed condition but becomes magnetic as a result of cold working.

Application

- Automotive exhaust system: Exhaust flexible pipes, Exhaust manifolds, Automotive trim etc.

- Train car exterior components, like the siding or the base along the lower edge of a car, etc.

- Deep drawning kitchen equipment: Cookware, sinks, kitchen utensils, and food service equipment.

- Architectural applications: door, windows, hose clamps, stair frames, hinges, etc.

- Decorative pipe, industrial pipe.

- Other outdoor appliances: Grills, guardrails on highways, highway signs, other general signage, etc.

- Banding & strapping.

Type 201 can be used in many applications because of its wide range of mechanical properties in annealed and cold-worked conditions. The selection of the type of stainless steel needs to consider the following points: Appearance requests, air corrosion and the cleaning ways to be adopted, and then take into account the requirements of cost, aesthetics standard, corrosion resistance, etc..

Additional Services

Coil slitting

Slitting stainless steel coils into smaller width strips

Capacity:

Material thickness: 0.03mm-3.0mm

Min/Max slit width: 10mm-1500mm

Slit width tolerance: ±0.2mm

With corrective leveling

Coil cutting to length

Cutting coils into sheets on request length

Capacity:

Material thickness: 0.03mm-3.0mm

Min/Max cut length: 10mm-1500mm

Cut length tolerance: ±2mm

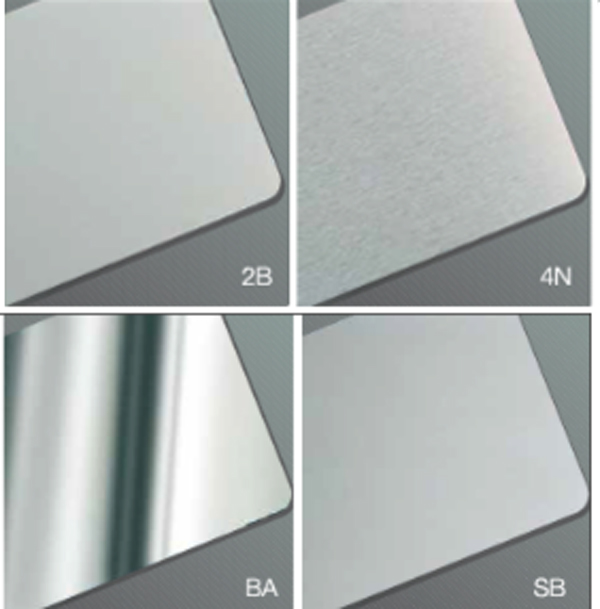

Surface treatment

For the purpose of decoration usage

No.4, Hairline, Polishing treatment

Finished surface will be protect by PVC film