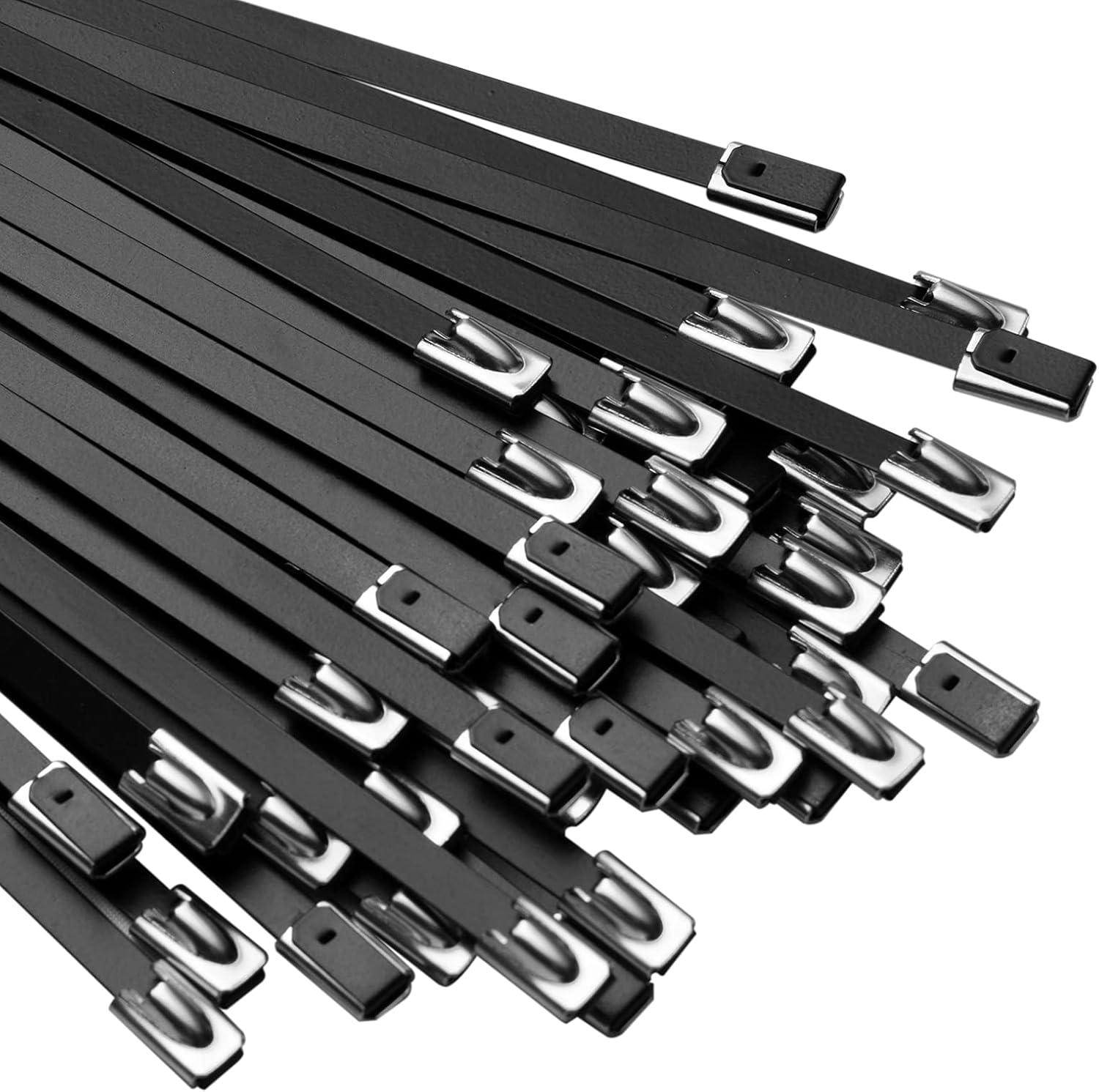

Stainless steel cable ties-Ball self-locking type

Product features

Materials:201,304,316 Stainless Steel.Length can be customized. OEM service is available.

Features:Acid-resistance,corrosion-resistance,high tensile strength,easy and fast operation and other advantages.

Temperature Range:-60℃ to 550℃

Product parameters

|

Part No. |

Length mm(inch) |

Width mm(inch) |

Thickness(mm) |

Max.bundle dia.mm(inch) |

Min.loop tensile Strength N(Ibs) |

Pcs/bag |

|

Z4.6x150 |

150(5.9) |

4.6(0.181) |

0.25 |

37(1.46) |

600(135) |

100 |

|

Z4.6x200 |

200(7.87) |

0.25 |

50(1.97) |

100 |

||

|

Z4.6x250 |

250(9.84) |

0.25 |

63(2.48) |

100 |

||

|

Z4.6x300 |

300(11.8) |

0.25 |

76(2.99) |

100 |

||

|

Z4.6x350 |

350(13.78) |

0.25 |

89(3.5) |

100 |

||

|

Z4.6x400 |

400(15.75) |

0.25 |

102(4.02) |

100 |

||

|

Z4.6x450 |

450(17.72) |

0.25 |

115(4.53) |

100 |

||

|

Z4.6x500 |

500(19.69) |

0.25 |

128(5.04) |

100 |

||

|

Z4.6x550 |

550(21.65) |

0.25 |

141(5.55) |

100 |

||

|

Z4.6x600 |

600(23.62) |

0.25 |

154(6.06) |

100 |

||

|

Z7.9x150 |

150(5.9) |

7.9(0.311) |

0.25 |

37(1.46) |

800(180) |

100 |

|

Z7.9x200 |

200(7.87) |

0.25 |

50(1.97) |

100 |

||

|

Z7.9x250 |

250(9.84) |

0.25 |

63(2.48) |

100 |

||

|

Z7.9x300 |

300(11.8) |

0.25 |

76(2.99) |

100 |

||

|

Z7.9x350 |

350(13.78) |

0.25 |

89(3.5) |

100 |

||

|

Z7.9x400 |

400(15.75) |

0.25 |

102(4.02) |

100 |

||

|

Z7.9x450 |

450(17.72) |

0.25 |

115(4.53) |

100 |

||

|

Z7.9x500 |

500(19.69) |

0.25 |

128(5.04) |

100 |

||

|

Z7.9x550 |

550(21.65) |

0.25 |

141(5.55) |

100 |

||

|

Z7.9x600 |

600(23.62) |

0.25 |

154(6.06) |

100 |

||

|

Z7.9x650 |

650(25.59) |

0.25 |

167(6.57) |

100 |

||

|

Z7.9x700 |

700(27.56) |

0.25 |

180(7.09) |

100 |

||

|

Z7.9x750 |

750(29.53) |

0.25 |

191(7.52) |

100 |

||

|

Z7.9x800 |

800(31.5) |

0.25 |

193(7.59) |

100 |

Features

Corrosion Resistance: Withstands exposure to moisture, chemicals, saltwater, and extreme temperatures.

High Tensile Strength: Supports heavy loads without deformation or breakage (typical tensile strength: 50-200+ lbs).

Temperature Resilience: Performs reliably in temperatures ranging from -40°C to 300°C (-40°F to 572°F).

Fire Resistance: Non-combustible and suitable for fire-prone or high-heat areas.

Re-usability: Can be adjusted or reused in certain designs, reducing waste.

Applications:

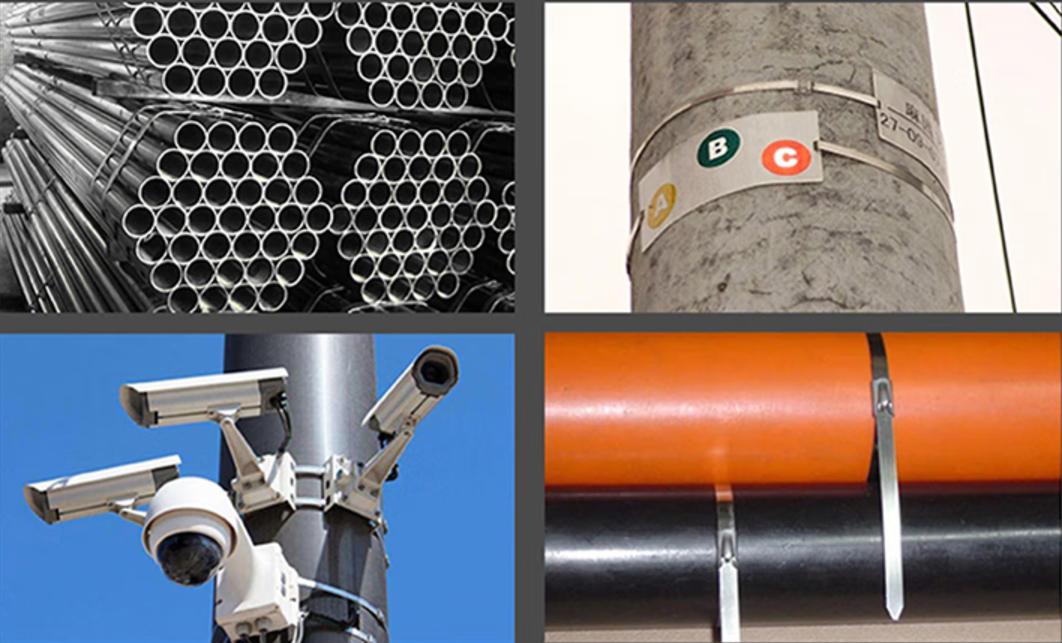

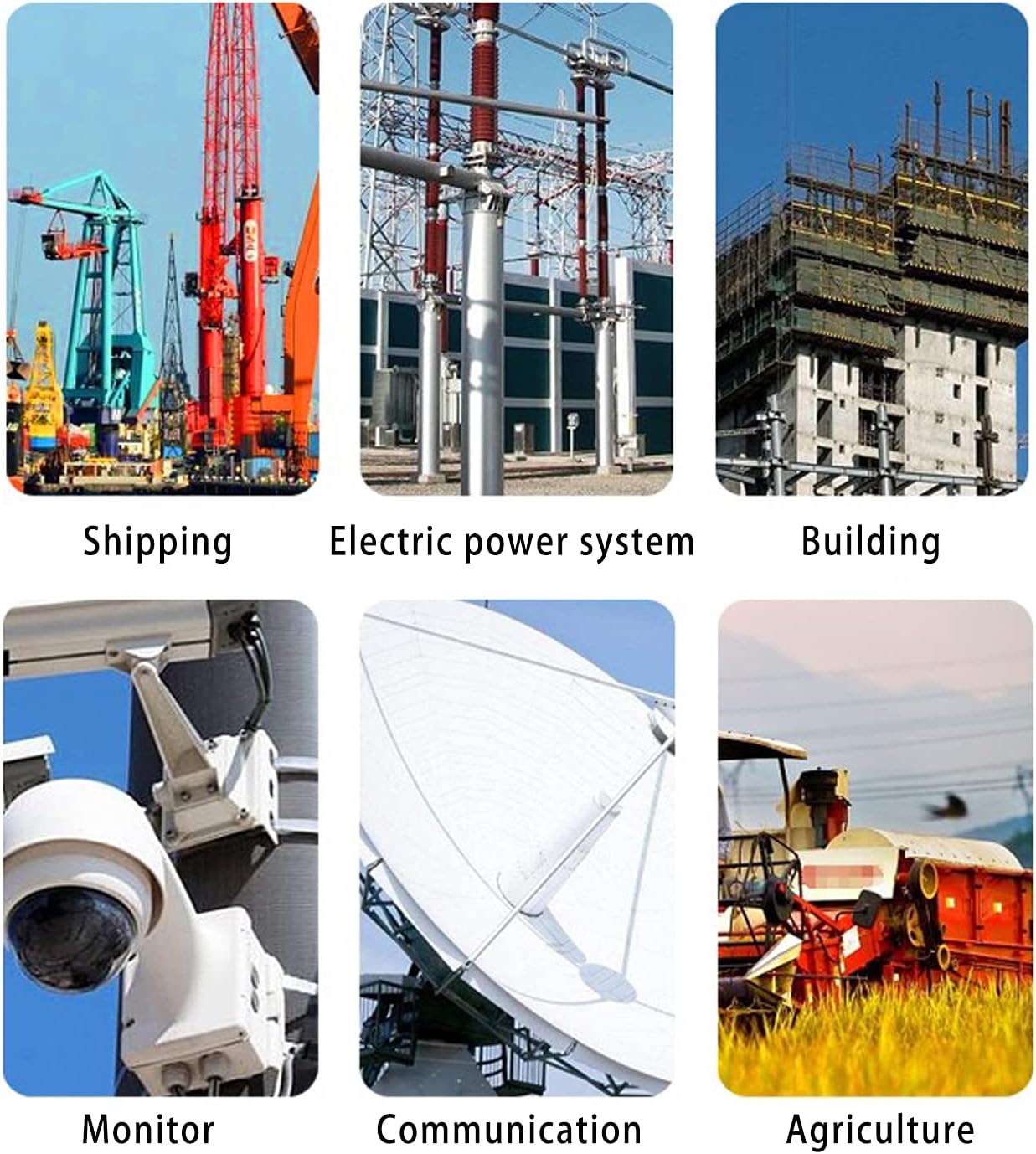

1. Marine & Offshore

Use Cases: Securing cables, pipes, and equipment on ships, oil rigs, and underwater structures.

Advantages: Resists saltwater corrosion, UV exposure, and harsh weather conditions.

Examples: Bundling hydraulic hoses, anchoring sonar systems, and fastening deck fixtures.

2. Automotive & Aerospace

Use Cases: Engine compartment wiring, fuel line organization, and aircraft component fixation.

Advantages: Withstands high vibrations, extreme temperatures (-40°C to 300°C), and chemical exposure.

Examples: Securing brake lines, aviation wiring harnesses, and EV battery management systems.

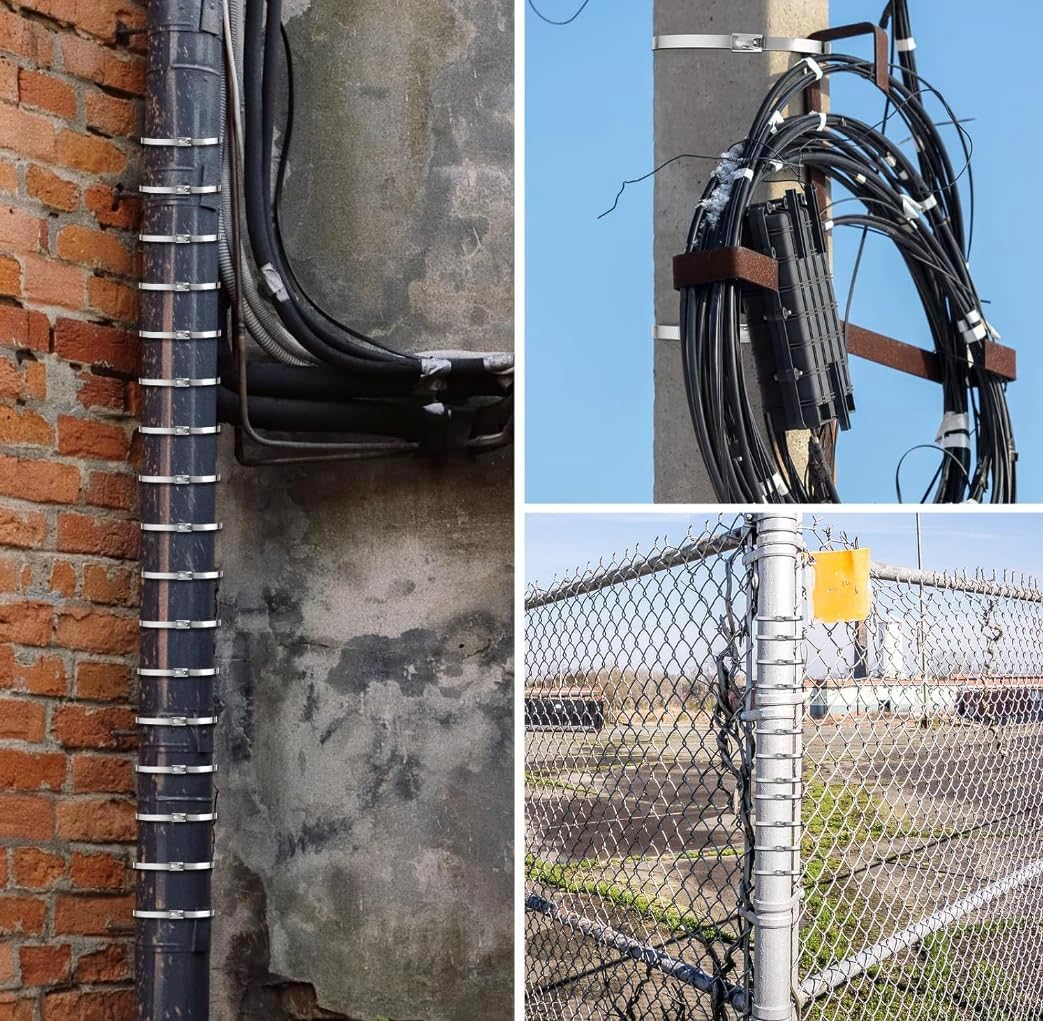

3. Construction & Infrastructure

Use Cases: Structural bundling in bridges, HVAC ducting, and outdoor electrical installations.

Advantages: Non-corrosive, fire-resistant, and ideal for load-bearing applications.

Examples: Reinforcing rebar, securing solar panel arrays, and organizing conduit systems.

4. Energy & Utilities

Use Cases: Power plants, wind turbines, and nuclear facilities.

Advantages: Immune to electromagnetic interference (EMI), radiation resistance, and long-term stability.

Examples: Managing high-voltage cables, securing coolant pipes, and maintaining reactor safety systems.

5. Chemical & Oil/Gas

Use Cases: Refineries, pipelines, and chemical processing units.

Advantages: Resists acids, alkalis, and hydrocarbons; ensures leak-proof fastening.

Examples: Securing flare stack wiring, bundling hydraulic fracturing equipment, and hazardous zone installations.

6. Food & Pharmaceutical

Use Cases: Hygienic environments requiring FDA-compliant materials.

Advantages: Easy to sanitize, non-toxic, and withstands steam cleaning.

Examples: Securing processing line tubing, organizing cleanroom equipment, and packaging machinery.

7. Renewable Energy

Use Cases: Solar farms, wind turbines, and hydroelectric plants.

Advantages: UV-resistant, maintains integrity in fluctuating temperatures, and reduces maintenance costs.

Examples: Mounting solar cables, securing turbine blade sensors, and anchoring hydro-power components.

8. Military & Defense

Use Cases: Field equipment, armored vehicles, and naval systems.

Advantages: Tamper-proof, EMI-resistant, and survives explosive environments.

Examples: Weapon system cable management, battlefield communication setups, and vehicle armor reinforcement.

Why Choose Stainless Steel Cable Ties?

Longevity: Outlast plastic ties by decades, even in abrasive environments.

Safety: Non-combustible and non-conductive (with optional coatings).

Sustainability: 100% recyclable, reducing environmental footprint.

Ideal for mission-critical applications, stainless steel cable ties deliver unmatched performance where failure is not an option.