OEM Best Stainless steel materials exporter Factories - High corrosion resistance 316L stainless steel materials – Xinjing

OEM Best Stainless steel materials exporter Factories - High corrosion resistance 316L stainless steel materials – Xinjing Detail:

Xinjing is a full-line processor, stockholder and service center for various of cold-rolled and hot-rolled stainless steel coils, sheets and plates, for over 20 years. Our cold-rolled materials all are rolled by 20 rolling mills, meet international standards, precision enough on flatness and dimensions. Our smart and precision cutting & slitting services can meet various demands, while the most skilled technical advises are always available.

Grade 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels. It has almost the same physical and mechanical properties as 304 stainless steel and contains a similar material makeup. The key difference is that 316 stainless steel incorporates about 2 to 3 percent molybdenum. The addition increases corrosion resistance, particularly against chlorides and other industrial solvents.

Products Attributes

- Excellent in a range of atmospheric environments and many corrosive media – generally more resistant than 304.

- 316 is usually regarded as the standard “marine grade stainless steel”, but it is not resistant to warm sea water.

- Good oxidation resistance in intermittent service to 870 °C and in continuous service to 925 °C. But continuous use of 316 in the 425-860 °C range is not recommended if subsequent aqueous corrosion resistance is important.

- Solution Treatment (Annealing) – Heat to 1010-1120 °C and cool rapidly, and it cannot be hardened by thermal treatment.

- Excellent weldability by all standard fusion methods, both with and without filler metals.

Application

- Industrial equipment is used in Pharmaceutical manufacturing & Chemical Manufacturing.

- Industrial and chemical transportation containers or tanks.

- Automotive exhaust system: Exhaust flexible pipes, Exhaust manifolds, etc.

- Pressure vessels.

- Medical equipment where non-surgical steel.

- Food production and processing in saline environments.

- Threaded fasteners.

The selection of the type of stainless steel needs to consider the following points: Appearance requests, air corrosion and the cleaning ways to be adopted, and then take into account the requirements of cost, aesthetics standard, corrosion resistance, etc.. For more information on this source please email or call.

Additional Services

Coil slitting

Slitting stainless steel coils into smaller width strips

Capacity:

Material thickness: 0.03mm-3.0mm

Min/Max slit width: 10mm-1500mm

Slit width tolerance: ±0.2mm

With corrective leveling

Coil cutting to length

Cutting coils into sheets on request length

Capacity:

Material thickness: 0.03mm-3.0mm

Min/Max cut length: 10mm-1500mm

Cut length tolerance: ±2mm

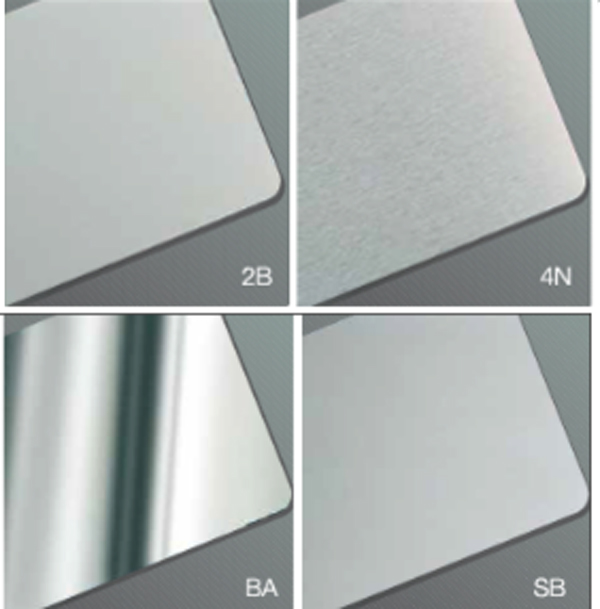

Surface treatment

For the purpose of decoration usage

No.4, Hairline, Polishing treatment

Finished surface will be protect by PVC film

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for OEM Best Stainless steel materials exporter Factories - High corrosion resistance 316L stainless steel materials – Xinjing, The product will supply to all over the world, such as: Barbados, South Korea, Angola, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.