OEM Best Mirror Finish Stainless Steel Sheet Factory - High quality 316 & 316L stainless steel coil supplying – Xinjing

OEM Best Mirror Finish Stainless Steel Sheet Factory - High quality 316 & 316L stainless steel coil supplying – Xinjing Detail:

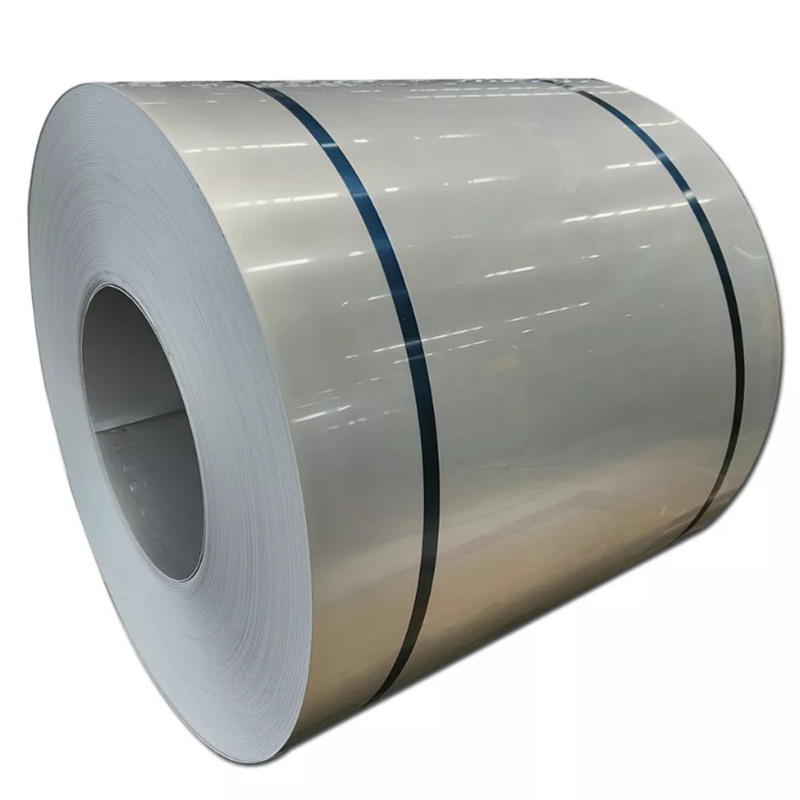

Xinjing is a full line processor, stockholder and service center for various of cold rolled and hot rolled stainless steel coils, sheets and plates, for over 20years. Our cold rolled materials all are rolled by 20 rolling mills, meet with international standards, precision enough on flatness and dimensions Our smart and precision cutting & slitting services can meet various demands, while most skilled technical advices are always avaliable.

Alloy 316/316L austenitic stainless steel developed to provide improved corrosion resistance to Alloy 304/304L, the corrosion performance of SS 304 is not enough, 316/316L is often consider as the first alternate. The higher Nickel content in 316 and 316L over SS 304 and the Molybdenum addition in 316 and 316L gives it an edge in performance in corrosive and high temperature environments. It is often utilized in process streams containing chlorides or halides. The addition of molybdenum improves general corrosion and chloride pitting resistance. It also provides higher creep, stress-to-rupture and tensile strength at elevated temperatures.

“The difference between the 316 and 316L grades is the quantity of carbon contained. The L stands for low carbon, both L grades contain a maximum 0.03% carbon, while the standard grades can comprise up to 0.07% carbon. In most instances, the corrosion resistance of Alloys 316 and 316L will be roughly equal in most corrosive environments. However, in environments that are sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones Alloy 316L should be used because of its low carbon content.

Products Attributes

- Stainless steel 316/316L resists atmospheric corrosion, as well as, moderately oxidizing and reducing environments.

- Resist corrosion in polluted

- marine atmospheres.

- 316/316L is non-magnetic in the annealed condition, but can become slightly magnetic as a result of cold working or welding.

- 316/316L stainless is non-hardenable by heat treatment and can be readily formed and drawn

- Rupture and tensile strength at high temperatures

- Can be easily welded and processed by standard shop fabrication practices.

Application

- Chemical and Petrochemical Processing — pressure vessels, tanks, heat

- Food handling and processing equipments: Cookwares, tablewares, milking machines, food storage tanks, coffee pots, etc.

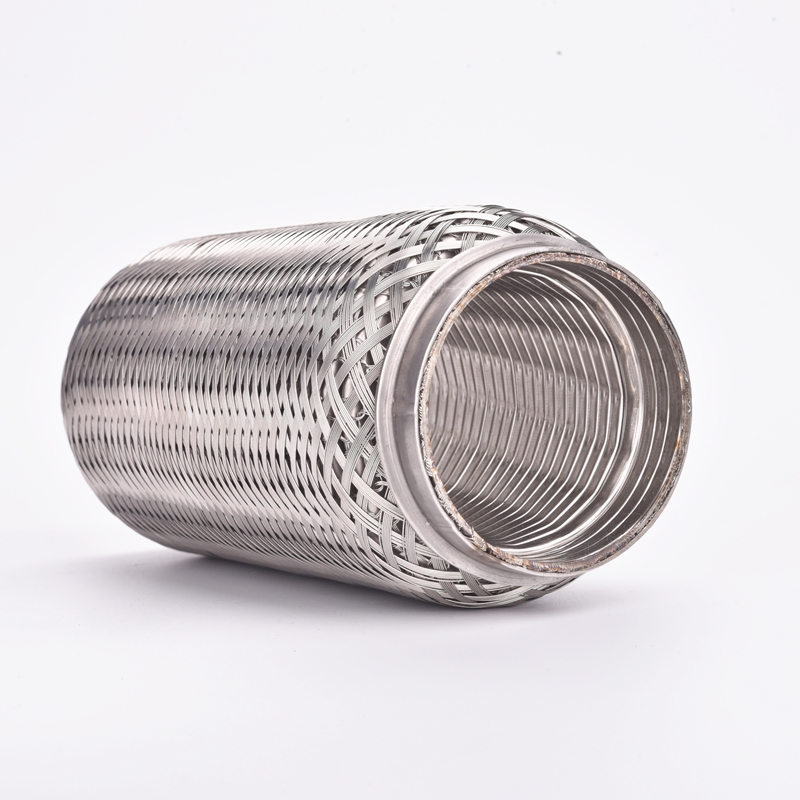

- Automotive exhaust system: Exhaust flexible pipes, Exhaust manifolds, etc.

- Marine

- Medical

- Petroleum Refining

- Pharmaceutical Processing

- Power Generation — nuclear

- Pulp and Paper

- Textiles

- Water Treatment

The selection of the type of stainless steel needs to consider the following points: Appearance requests, air corrosion and the cleaning ways to be adopted, and then take into account the requirements of cost, aesthetics standard, corrosion resistance, etc., 304 stainless steel performances pretty effective in dry indoor environment.

Additional Services

Coil slitting

Slitting stainless steel coils into smaller width strips

Capacity:

Material thickness: 0.03mm-3.0mm

Min/Max slit width: 10mm-1500mm

Slit width tolerance: ±0.2mm

With corrective leveling

Coil cutting to length

Cutting coils into sheets on request length

Capacity:

Material thickness: 0.03mm-3.0mm

Min/Max cut length: 10mm-1500mm

Cut length tolerance: ±2mm

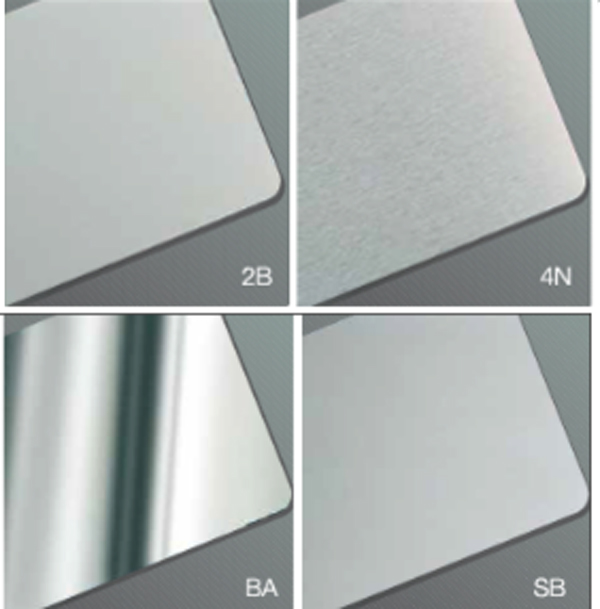

Surface treatment

For the purpose of decoration usage

No.4, Hairline, Polishing treatment

Finished surface will be protect by PVC film

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for OEM Best Mirror Finish Stainless Steel Sheet Factory - High quality 316 & 316L stainless steel coil supplying – Xinjing, The product will supply to all over the world, such as: Chicago, Durban, Eindhoven, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!