OEM Best Exhaust Flexible Tube Manufacturers - Exhaust Flexible Pipes Unlined – Xinjing

OEM Best Exhaust Flexible Tube Manufacturers - Exhaust Flexible Pipes Unlined – Xinjing Detail:

NINGBO CONNECT AUTO PARTS CO., LTD is a brother company of Xinjing, a manufacturing plant producing exhaust flex pipes, exhaust bellows, corrugated pipes, flexible tubes and mounting components for road vehicles. Connect currently exports to over 30 countries worldwide, offering long-term partnership solutions to customers seeking reliability and high-quality flexible pipes products in the aftermarket &OE market.

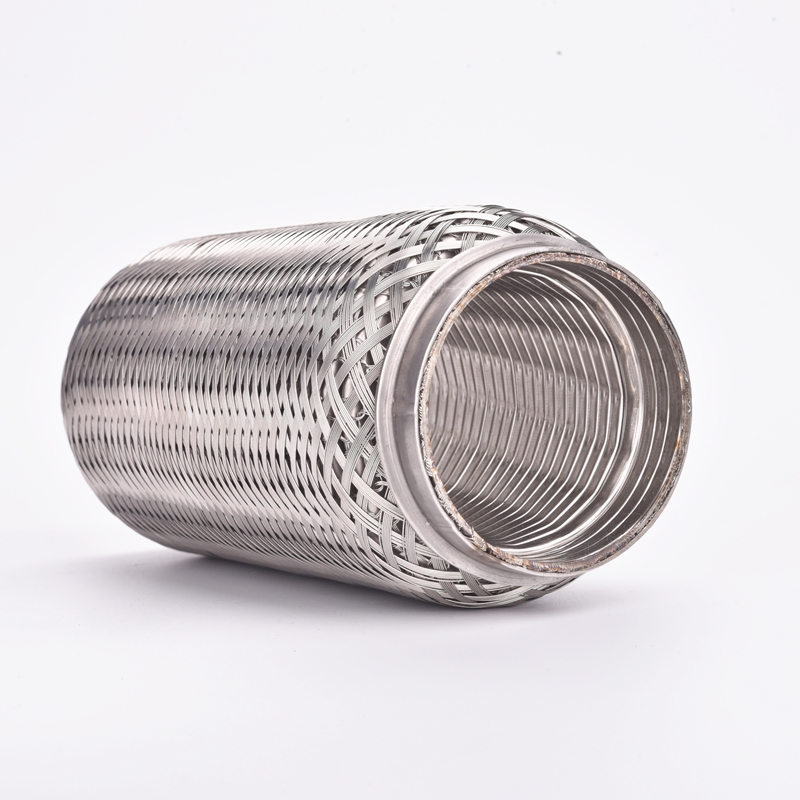

Stainless steel exhaust flexible pipes in a gas-tight, double-walled and streamlined design suitable for design and manufacture of exhaust systems, as well as for repair of defective exhaust systems. The unlined exhaust flexible pipe is the most basic type without inner liner. It container a bellows with outer braids that allows a greater elasticity in terms of compression and elongation along the longitudinal axe.

PRODUCT RANGE

Specifications

| Part No. | Inner Diameter(ID) | Overall length(L) | ||

| Inch | mm | Inch | mm | |

| K13404 | 1-3/4″ | 45 | 4″ | 102 |

| K13406 | 1-3/4″ | 45 | 6″ | 152 |

| K13407 | 1-3/4″ | 45 | 7″ | 180 |

| K13408 | 1-3/4″ | 45 | 8″ | 203 |

| K13409 | 1-3/4″ | 45 | 9″ | 230 |

| K13410 | 1-3/4″ | 45 | 10″ | 254 |

| K13411 | 1-3/4″ | 45 | 11″ | 280 |

| K13412 | 1-3/4″ | 45 | 12″ | 303 |

| K20004 | 2″ | 50.8 | 4″ | 102 |

| K20006 | 2″ | 50.8 | 6″ | 152 |

| K20008 | 2″ | 50.8 | 8″ | 203 |

| K20009 | 2″ | 50.8 | 9″ | 230 |

| K20010 | 2″ | 50.8 | 10″ | 254 |

| K20011 | 2″ | 50.8 | 11″ | 280 |

| K20012 | 2″ | 50.8 | 12″ | 303 |

| K21404 | 2-1/4″ | 57.2 | 4″ | 102 |

| K21406 | 2-1/4″ | 57.2 | 6″ | 152 |

| K21408 | 2-1/4″ | 57.2 | 8″ | 203 |

| K21409 | 2-1/4″ | 57.2 | 9″ | 230 |

| K21410 | 2-1/4″ | 57.2 | 10″ | 254 |

| K21411 | 2-1/4″ | 57.2 | 11″ | 280 |

| K21412 | 2-1/4″ | 57.2 | 12″ | 303 |

| K21204 | 2-1/2″ | 63.5 | 4″ | 102 |

| K21206 | 2-1/2″ | 63.5 | 6″ | 152 |

| K21208 | 2-1/2″ | 63.5 | 8″ | 203 |

| K21209 | 2-1/2″ | 63.5 | 9″ | 230 |

| K21210 | 2-1/2″ | 63.5 | 10″ | 254 |

| K21211 | 2-1/2″ | 63.5 | 11″ | 280 |

| K21212 | 2-1/2″ | 63.5 | 12″ | 305 |

| K30004 | 3″ | 76.2 | 4″ | 102 |

| K30006 | 3″ | 76.2 | 6″ | 152 |

| K30008 | 3″ | 76.2 | 8″ | 203 |

| K30010 | 3″ | 76.2 | 10″ | 254 |

| K30012 | 3″ | 76.2 | 12″ | 305 |

| Part No. | Inner Diameter(ID) | Overall length(L) | ||

| Inch | mm | Inch | mm | |

| K42120 | 42 | 120 | ||

| K42165 | 42 | 165 | ||

| K42180 | 42 | 180 | ||

| K50120 | 50 | 120 | ||

| K50165 | 50 | 165 | ||

| K55120 | 55 | 120 | ||

| K55165 | 55 | 165 | ||

| K55180 | 55 | 180 | ||

| K55200 | 55 | 200 | ||

| K55250 | 55 | 250 | ||

| K60160 | 60 | 160 | ||

| K60200 | 60 | 200 | ||

| K60240 | 60 | 240 | ||

| K65150 | 65 | 150 | ||

| K65200 | 65 | 200 | ||

| K70100 | 70 | 100 | ||

| K70120 | 70 | 120 | ||

| K70150 | 70 | 150 | ||

| K70200 | 70 | 200 | ||

( Other ID 38, 40, 48, 52, 80mm … and other lengthes are on request )

Features

- Isolate vibration generated by the engine; thereby relieving stress on the exhaust system.

- Reduce premature cracking of manifolds and downpipes and help extend the life of other components.

- Applicable to different positions of the exhaust system, most effective when installed in front of the pipe section of the exhaust system.

- Double wall stainless steel for ensuring durability, technically gas-tight.

- Made of high temperature resistant & highly corrosion resistant material.

- Available in all standard sizes.

- Not recommended for turbocharged applications.

Quality Control

Every-single unit is tested at least twice through-out the manufacturing cycle

The first test is a visual inspection. The operator makes sure that:

- The part is placed in its fixture to ensure proper fitment on the vehicle.

- The welds are completed without any holes or gaps.

- The ends of the pipes are fished to the proper specifications.

The second test is a pressure test. The operator blocks all of the entrances and exits of the part and fills it with compressed air with a pressure equal to five times that of a standard exhaust system. This guarantees the structural integrity of the welds holding the piece together.

With over 10 years of experience, we will constantly enrich our technical and service skills, to win the trust of customers with our enthusiasm and sincerity, achieve win-win in cooperation and seek common development and growth with distinguished customers, suppliers and fellows.

Production Line

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for OEM Best Exhaust Flexible Tube Manufacturers - Exhaust Flexible Pipes Unlined – Xinjing, The product will supply to all over the world, such as: Malawi, Buenos Aires, Armenia, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!